Vakum Freeze Dryer Tradisional

● Pilihan kalawan fungsi pre-katirisan, euweuh gudang pre-katirisan éksternal, pikeun ngajawab liquefaction mobile bahan jeung resiko polusi;

● The freeze-garing chamber na rak dijieun luyu ketat jeung sarat GMP. chamber dijieunna tina SUS304 kelas stainless steel, sarta internal ieu eunteung digosok.

● chamber The adopts tiis bubu desain terpadu, struktur kompak, gampang pikeun ngabersihan, euweuh Saniter maot Angle, sarta boga jandela tetempoan observasi;

● bubu tiis nu catcher cai ngagunakeun Saniter kelas stainless steel processing SUS304, aréa kondensasi leuwih gede dibandingkeun produk sarupa 50%, bisa shorten waktu freeze drying, ngurangan biaya produksi;

● rak bisa ngaropéa nurutkeun sarat customer of D31(6363) bahan alloy aluminium pikeun pengobatan anodizing atanapi SUS304 rak stainless steel;

● Sistim refrigeration utamana diimpor merek, kalawan refrigeration kuat, cooling gancang, kinerja stabil sarta dipercaya;

● Nurutkeun kana bahan jeung customer perlu nyadiakeun rupa-rupa unit pompa vakum;

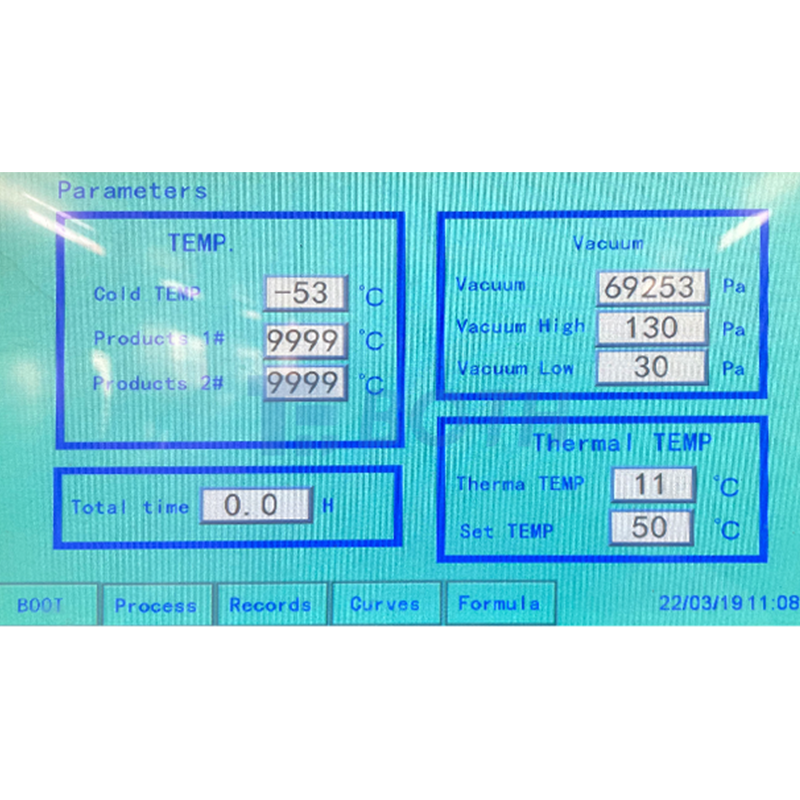

● Sistim kontrol purwakarta adopts Siemens purwakarta kontrol otomatis, operasi basajan, nurutkeun prosés produksi perlu wenang pindah mode kontrol jeung setélan parameter, pikeun minuhan sarat bahan béda prosés freeze-drying;

● 7 inci warna nyata layar LCD touch, real-time ngarékam mintonkeun bubu tiis, bahan, suhu rak jeung gelar vakum, ngahasilkeun kurva drying;

SUS304 Stainless Steel Awak Utama

Awak utama dijieunna tina Saniter stainless steel SUS304 stainless steel, luyu jeung standar GMP.

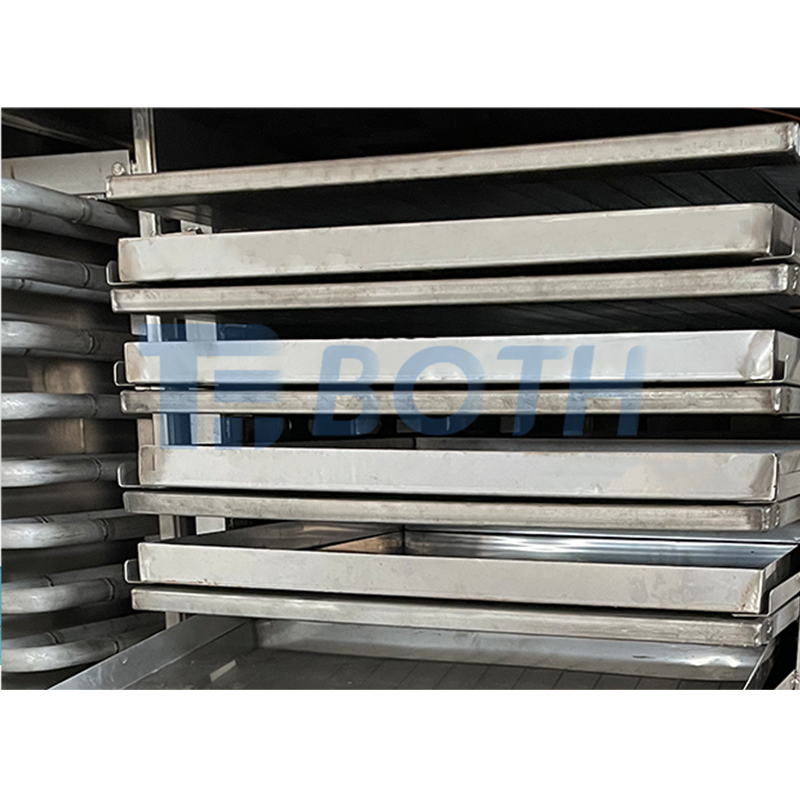

Rak

Rak bisa ngaropéa nurutkeun sarat customer of D31 (6363) bahan alloy aluminium pikeun pengobatan anodizing atanapi SUS304 rak stainless steel, permukaan lemes seragam pangaruh konduksi panas.

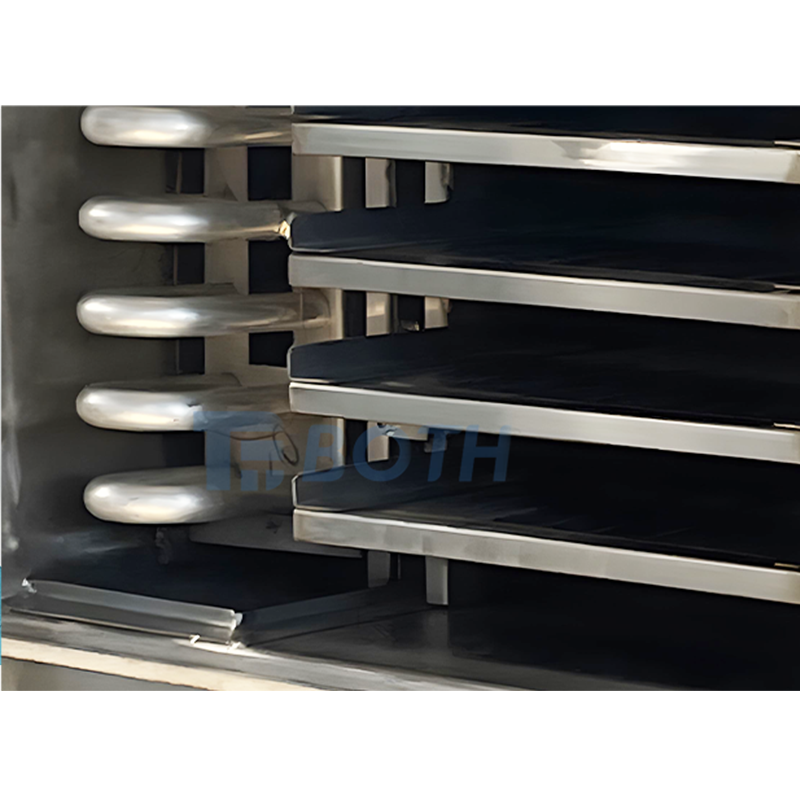

Perangkap Tiis

Tiis bubu yén Cai Catcher ngagunakeun Saniter kelas stainless steel processing SUS304, aréa kondensasi leuwih gede dibandingkeun produk sarupa 50%, bisa shorten waktu freeze drying, ngurangan biaya produksi;

Sistim Kontrol PLC

Sistim kontrol PLC adopts Siemens PLC kontrol otomatis, operasi basajan, nurutkeun prosés produksi perlu wenang pindah mode kontrol jeung parameter Setélan, Taiwan WEINVIEW layar toél, operasi basajan.

Brand Inohong Internasional

Dunya Brand Compressor Unit: Italia FRASCOLD, Jérman BITZER, AS EMERSON COPELAND, Italia DORIN, Perancis TECUMSEH, Brazil EMBRAC, jsb kalawan efisiensi refrigeration tinggi jeung kinerja stabil.

BTFD-1(1m2)

BTFD-5(5m2)

BTFD-20(20m2)

BTFD-100(100m2)

| Modél | BTFD-1 | BTFD-5 | BTFD-10 | BTFD-20 | BTFD-50 | BTFD-100 |

| Rak Éfisién Drying Area | 1 ㎡ | 5 ㎡ | 10 ㎡ | 20 ㎡ | 50 ㎡ | 100 ㎡ |

| Kapasitas prosés / Mandi (Bahan Baku) | 12 kg / sapotong | 60 kg / sapotong | 120 kg / sapotong | 240 kg / sapotong | 600 kg / sapotong | 1200 kg / sapotong |

| Sasayogian tanaga | 380V / 50Hz atanapi ngaropéa | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz | 380V / 50Hz |

| Daya dipasang | 6kw | 16kw | 24kw | 39kw | 125kw | 128kw |

| Konsumsi Daya Rata | 3 kilowatt jam | 6 kilowatt jam | 12 kilowatt jam | 22 kilowatt jam | 70 kilowatt jam | 75 kilowatt jam (peryogi boiler sorangan) |

| Ukuran (L * W * H) | 2000 * 1000 * 1500mm | 3000 * 1400 * 1700mm | 3800 * 1400 * 1850mm | 4100 * 1700 * 1950mm | 6500 * 2100 * 2100mm (ngawangun silinder) | 10600 * 2560 * 2560mm (ngawangun silinder) |

| Beurat | 800 kg | 1500 kg | 3000 kg | 40000 kg | 15000 kg | 30000 kg |

| Matrial Trays | 645 * 395 * 35 mm | 600 * 580 * 35mm | 660 * 580 * 35 mm | 750 * 875 * 35 mm | 610 * 538 * 35 mm | 610 * 610 * 35mm |

| Dulang No. | 4 buah | 14 PCS | 26 PCS | 30 PCS | 156 PCS | 306 PCS |

| bubu tiis / Cai Catcher Temp. | ≤-45 ℃ | |||||

| Rak Temp. | RT-95 ℃ | RT-95 ℃ | RT-95 ℃ | RT-95 ℃ | RT-95 ℃ | RT-95 ℃ |

| Gelar vakum | ≤10pa | ≤10pa | ≤10pa | ≤10pa | ≤60pa | ≤60pa |

| Bahan Awak Utama | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 | Stainless Steel SUS 304 |

| Kompresor | Jérman BITZER | Jérman BITZER | Itali FRASCOLD | Itali FRASCOLD | Taiwan Fusheng | Taiwan Fusheng |

| Daya Kompresor | 2P | 8P | 10P | 10P * 2 Susunan | 50KW | 75KW |

| Cairan sirkulasi termal | Panas Ngalaksanakeun Minyak Silikon / Cai Dimurnikeun | |||||

| Modeu Kontrol | PLC Manual / PLC Otomatis | |||||

| Kontrol Asesoris Listrik | CHINT / Siemens | |||||

| Layar cabak | Taiwan WEINVIEW | |||||

| Catetan: | 1-20m² nyaéta Square Integrated Vacuum Freeze Dryer (Vacuum, Refrigeration System & Drying chamber Integrated), 50-200m² nyaéta Round Split Vacuum Freeze Dryer. | |||||